Part Gaging

- Used with PGS series grippers for easy part removal

- Rods can be moved in several different positions

- Rods can be custom made per customer specifications to stabilize parts during transfer

- Can be used to position parts

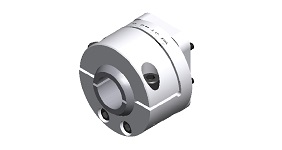

Spherical Mount

- PGS10CLPSPXXXX accomodates 1.00" round, 1.25" round,

25 mm round,19 mm square & 25 mm square tubes

- Spherical ball clamp allows 360° rotation and 30° of angular adjustment

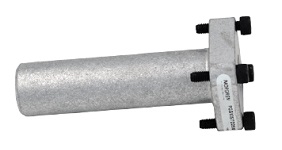

Internal Wire Gripper Mount Adapter

- Provides telescoping adjustment of gripper position

- Provides entry point for Pico style sensor cable into finger

- Telescoping O.D. sized for insertion into standard IMI Norgren Versa 1.25" O.D. finger link or tubing

Internal Wire Gripper Mount

Adapter for Hot Metal Grippers

- Specifically designed to be used with slotted IMI Norgren Versa Links (SVL34BSLXXXX) to provide telescoping adjustment

- Two O-rings provided to attach to PGS10HXXXXXXXX8X or PGS10HXXXXXXXX9X Hot Metal Gripper

- Can only be used with the hot metal PGS grippers (PGS10H)

- Compatible only with the PICO sensor cable

Telescope & Stud Mounts

- PGS10STDXXXX provide mounting stud compatible with various diameter

tooling components

- PGS10TEL20 and PGS10TEL40 are internal wire gripper mount adapters compatible with the slotted IMI Norgren Versa-links (SVL30BSLXXXX) to provide telescoping adjustment

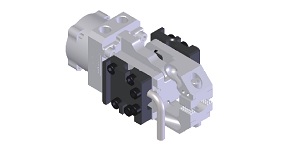

3 Bolt Clamp

- PGS10CLX3BXXXXX provides 360º rotation of gripper independent of ball

- PGS10CLX3BXXXXX accommodates 1.00" round, 1.25" round, 19 mm square,

25 mm square tubes and 25 mm round - Spherical ball clamp allows 360º rotation and 30º angular adjustment

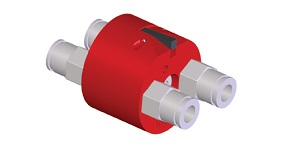

PGS Gripper Valve

- Redirects air from the gripper “closed” air port to the gripper “open” air port

- “Vents” or shuts air off to a single gripper without turning air off the entire system

- Mounts in-line with grippers or rail receivers

- Easily release incorrectly gripped panels

- Formerly known as Syron Gripper Valve

Buy Accessories